How Are Bulk Gym Flooring Orders Made and Delivered?

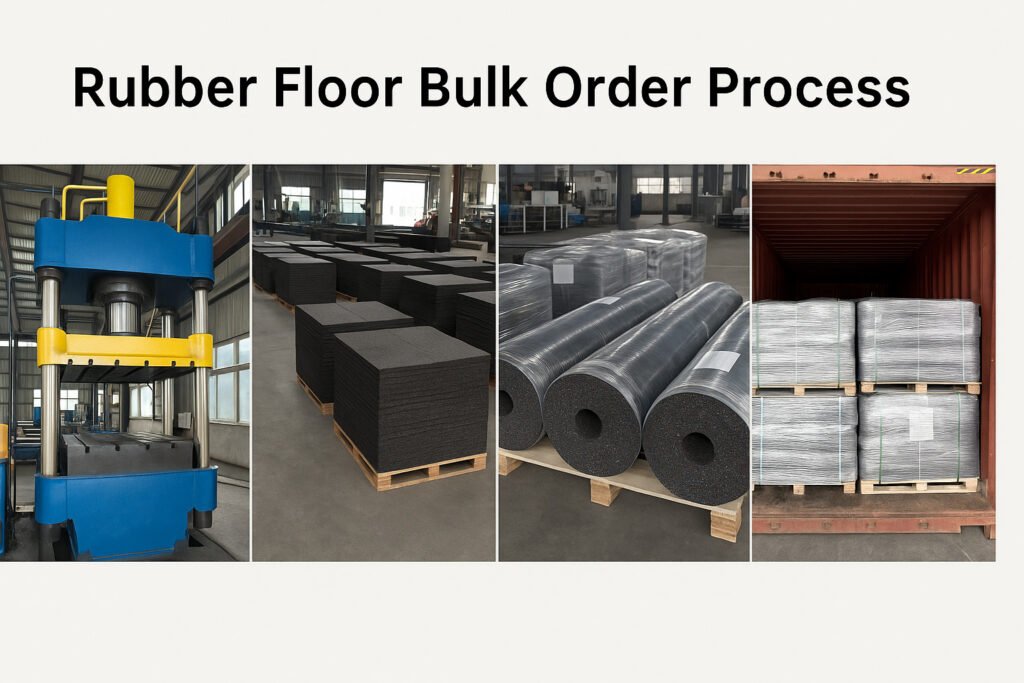

Ordering rubber flooring in bulk may seem simple—but what happens behind the scenes at the factory?

If you’re managing bulk gym flooring orders, here’s what really happens from factory to delivery.

Bulk gym flooring orders go through a strict process at Lanhefloor, from raw material preparation and mold pressing to packaging and global shipping, ensuring quality and timely delivery.

What is the production process for bulk rubber gym tiles?

Our gym tiles are made with high-pressure mold pressing using fine SBR or EPDM granules, delivering consistent quality, safety, and durability.

Tile Production Workflow

| Step | Description |

|---|---|

| 1 | Granules mixed per color and density spec |

| 2 | Poured into high-pressure heated molds |

| 3 | Compressed and cooled for stability |

| 4 | Demolded and QC-checked |

| 5 | Stacked and labeled before packing |

For composite tiles, we bond an EPDM roll top during molding to create a seamless high-performance surface.

How do we handle bulk orders for rubber rolls?

Lanhefloor rubber rolls are cut to custom lengths, wrapped, labeled, and stacked for seamless installation.

✅ Explore Gym Rubber Roll Products

| Specification | Details |

|---|---|

| Thickness | 4mm–12mm |

| Width | 1.0m or 1.25m |

| Roll Length | 8–15m (customizable) |

| Surface | SBR or EPDM speckled blend |

| Finish | Smooth, semi-matte |

Each roll is QC checked to ensure your bulk gym flooring orders meet safety and durability standards.

What kind of export packaging do we use?

Lanhefloor uses international-standard packaging to protect goods during shipping.

| Product | Packaging Details |

|---|---|

| Rubber Tiles | On pallets, cardboard layered, stretch-wrapped, labeled |

| Rubber Rolls | Individually film wrapped, kraft covered, palletized or stacked |

| EPDM Granules | Woven or PE bags, 25kg or jumbo size, shrink-wrapped, logo optional |

🔗 Export Packaging Guidelines – UPS

How do we ship flooring orders globally?

Our team arranges full logistics, customs paperwork, and tracking for bulk gym flooring orders.

Export & Logistics Flow

- Lead Time: 10–15 production days + 12–20 days shipping

- Docs Provided: Commercial Invoice, Packing List, CO, CE/EN1177, Customs Forms

- Ports: Most orders ship via Qingdao Port

- Incoterms: FOB standard, CIF/DDP optional

- Tracking: Container info shared at loading

🔗 What Is a Commercial Invoice – DHL

Clients from Australia and New Zealand report consistent on-time deliveries.

✅ Conclusion

Whether you’re ordering rubber rolls or tiles, our bulk gym flooring orders process includes:

- Strict production control

- Moisture-safe, export-grade packaging

- Full documentation for customs

- Clear communication and tracking

📩 Planning to order gym flooring in bulk?

👉 Get a Quote Now or contact us at info@lanhefloor.com