Outdoor Rubber Flooring Manufacturer in China

Lanhefloor offers EN1177 & CE certified outdoor rubber tiles for playgrounds, parks, trails, and landscape surfaces. Built from weatherproof EPDM granules, our safety flooring delivers long-lasting durability and superior impact absorption

products

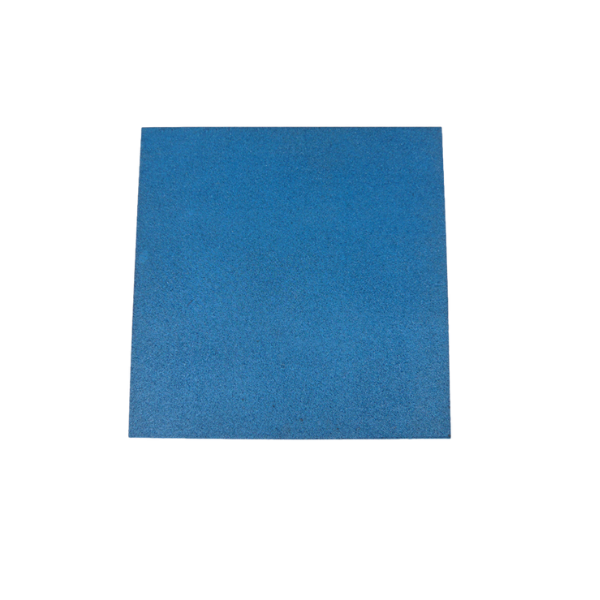

Outdoor Rubber Flooring Types We Offer

Choose from a wide range of EN1177-certified outdoor rubber floor solutions including safety tiles for playgrounds, pathways, tree surrounds, and more. Designed for high-traffic outdoor spaces with long-lasting performance and slip resistance

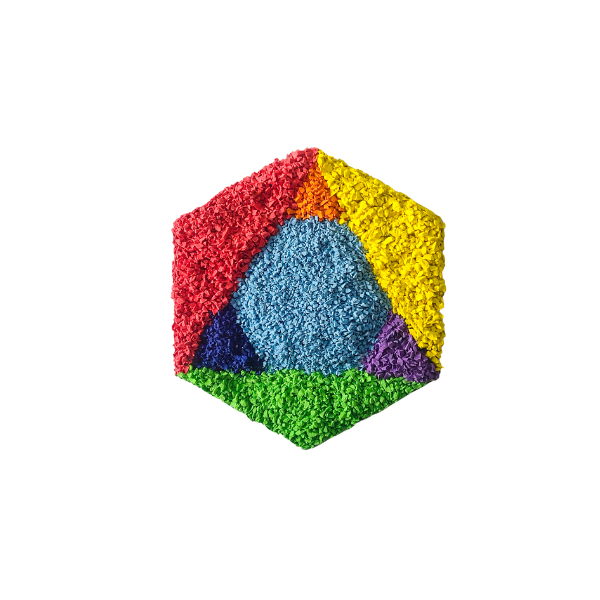

Playground Rubber Tiles

5 stars

Pathway Rubber Pavers

5 stars

Horse Stable Rubber Tiles

5 stars

Features

Why Choose Outdoor Rubber Flooring

Outdoor rubber flooring offers a slip-resistant, durable, and weatherproof solution for high-traffic outdoor spaces. It is widely used in playgrounds, walking paths, parks, horse stables, and public facilities.

Trusted by municipalities, schools, and contractors worldwide.

Anti-Slip Safety Surface

Provides a non-slip, impact-absorbing rubber surface ideal for playgrounds, schools, and public pathways

All-Weather Durability

Resists rain, UV rays, and temperature extremes. Designed for long-term outdoor rubber tile performance in all seasons.

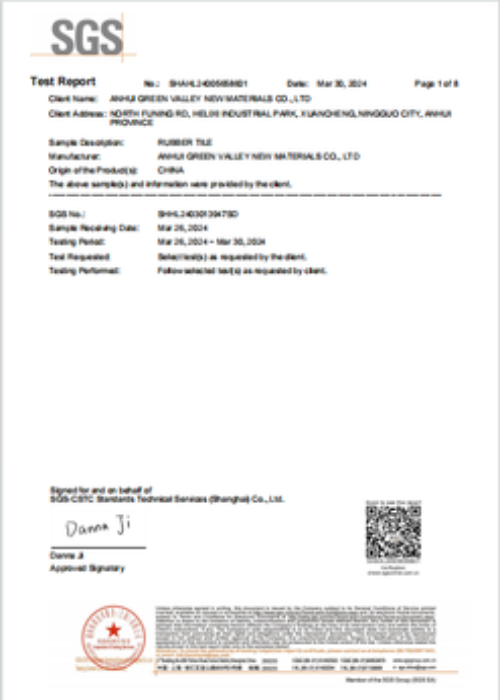

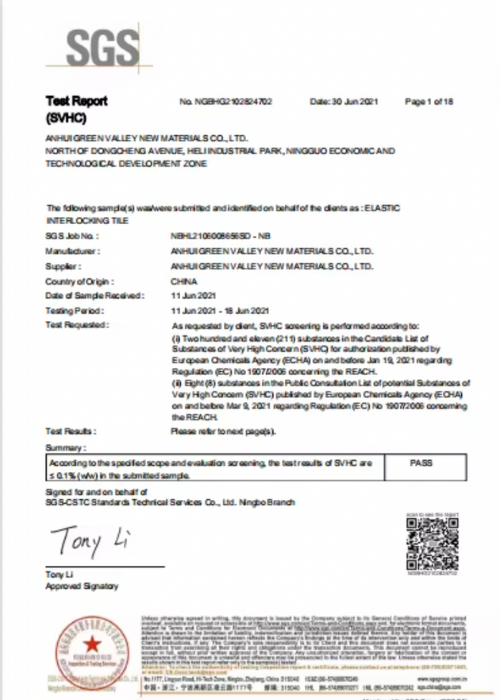

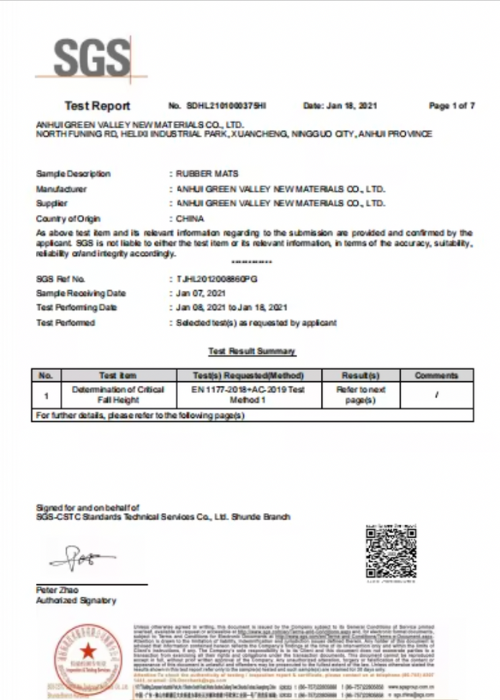

Certified Safety Guarantee

Certified to CE and EN1177 standards for safety and durability. Provides reliable impact protection in outdoor fitness or playground settings.

Fully Customizable Options

Choose from custom colors, sizes, and install types like interlocking, glue-down, or wet pour for rubber tile flexibility

Outdoor Rubber Flooring Specifications

Explore detailed specifications of outdoor rubber tiles for playgrounds, parks, trails, stables, and more. Find the right surface for your project.

| Tile Type | Size | Thickness | Surface | Installation | Application |

|---|---|---|---|---|---|

| Playground Rubber Tile | 500×500mm / 1000×1000mm | 25mm / 30mm / 40mm / 50mm | Colored SBR / EPDM | Glue-down / Dry Lay | School, Kindergarten, Parks |

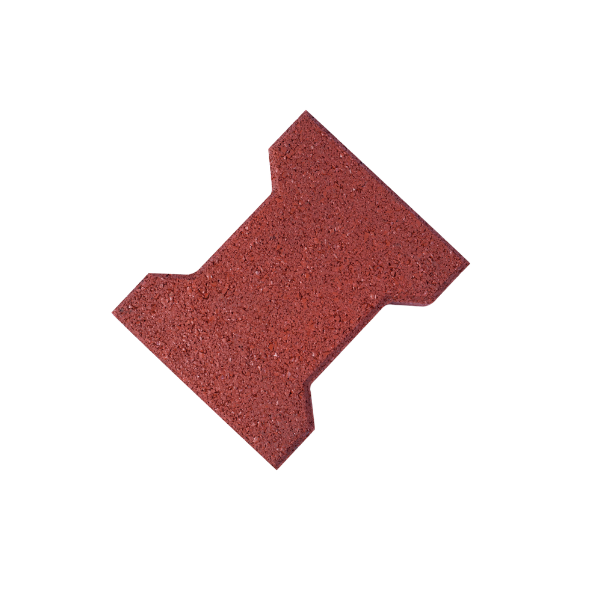

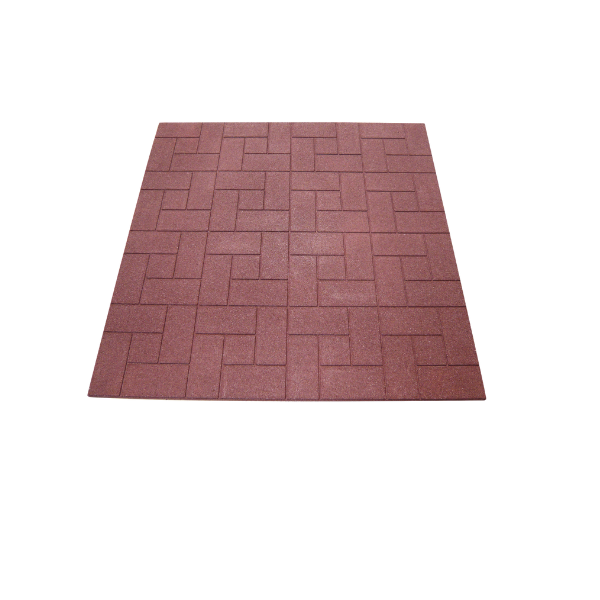

| Pathway Rubber Paver | Bone / Hexagon / 200x160mm | 20mm / 25mm / 30mm | Textured SBR | Dry Lay / Interlock | Parks, Gardens, Trails |

| Horse Stable Tile | 500x500mm | 30mm / 40mm / 50mm | Fine Granule SBR | Glue-down / Dry Lay | Horse Barns, Stables, Farms |

| Tactile Rubber Tile | 300x300mm / 400x400mm | 15mm / 20mm | Raised Dot / Line | Glue-down | Metro, Sidewalks, Accessibility Zones |

| Tree Ring Rubber Mat | Outer ⌀ 1000mm / Inner ⌀ 300mm | 40mm | Perforated / Drainage | Loose Lay / Embedded | Urban Landscaping, Tree Bases |

Solutions for various environments, providing the perfect flooring option for every need.

applications

Where to Use Outdoor Rubber Flooring

Discover how outdoor rubber tiles are used in playgrounds, parks, animal areas, and urban projects. Safe, durable, and designed for real-world use

- Outdoor safety tiles for kindergartens, preschools, and play areas

- Rubber pavers for jogging paths, park trails, and scenic walkways

- Heavy-duty rubber mats for horse barns, dog parks, and stables

- Tree ring rubber mats for urban landscaping and drainage zones

- Tactile tiles for sidewalks, metro stations, and crosswalks

- Wet pour EPDM surfaces for schools, stadiums, and running tracks

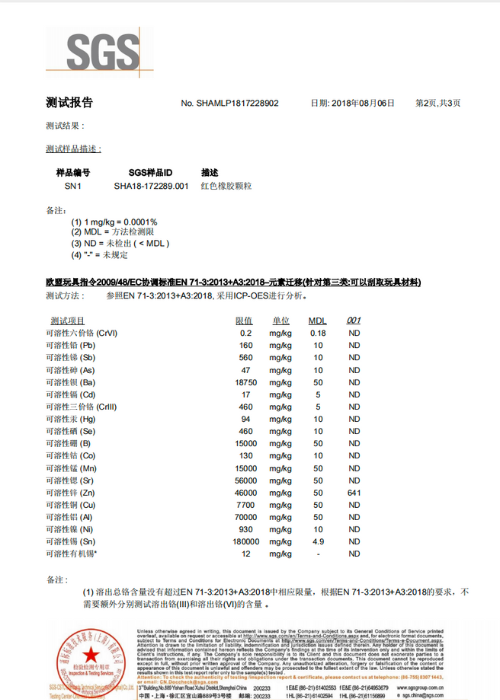

process

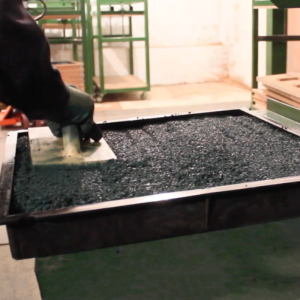

How Rubber Floor Tiles Are Made – Production Process Step by Step

Discover how Lanhefloor manufactures high-quality rubber tiles using advanced mixing, molding, vulcanization, and cooling techniques.

Rubber granules and adhesive are mixed in specific proportions.

Molds are heated and pressed for vulcanization.

The mixture is placed in molds. For composite tiles, rubber roll skin is placed at the mold's bottom.

Tiles are removed and allowed to cool and dry.

pack and ship

Secure Packaging & Global Shipping for Outdoor Rubber Tiles

At Lanhefloor, we use heavy-duty packaging solutions to protect every rubber tile during transit.

Each pallet is securely shrink-wrapped, labeled, and reinforced for maximum safety.

We collaborate with trusted freight forwarders and ship globally — ensuring that your outdoor rubber tiles arrive in perfect condition, on schedule, and ready for installation.

steps of installation

How to install rubbert tile

1.Preparation

Ensure the surface is clean and level.

2.Layout

Plan the layout to minimize cutting and ensure a uniform look.

3.Adhesive

Apply adhesive to the back of each tile or the floor surface.

4.Placement

Place tiles firmly, ensuring there are no gaps.

5.Trimming

Aliquet adipiscing vivamus ultrices ipsum, commodo vitae, elit nec ipsam luctus.

6.Curing

Allow the adhesive to cure properly.

projects

Real Projects Around the World

“Used in 100+ projects globally across AU, CA, SG, ME, EU”

Need Help?

FAQs

Find answers to common questions about our rubber tiles, including product details, installation, maintenance, and ordering.

What sizes are available?

Standard sizes are 500mm x 500mm and 1000mm x 1000mm. Custom sizes can be requested

What colors can I choose from?

We offer a range of colors including red, blue, green, and custom colors to meet your specific needs.

Can I request samples before placing a bulk order?

Yes, we can provide samples for you to check the quality and color before making a bulk purchase.

What payment methods do you accept?

30% TT before production, rest 70% before loading.

How long does it take to process an order?

Orders typically take 2-4 weeks to process, depending on the size and customization requirements.

How will my order be shipped?

We work with reliable logistics partners to ensure prompt and safe delivery of your order.

What should I do if my order arrives damaged?

Please contact us immediately if any items arrive damaged. We will arrange for replacements or refunds as necessary.

Do you offer discounts for bulk orders?

Yes, we offer competitive pricing and discounts for large orders. Contact us for more details

What if I need to change or cancel my order?

Changes or cancellations can be made within 24 hours of placing the order. Please contact us as soon as possible to make adjustments.

What kind of after-sales support do you provide?

We offer comprehensive after-sales support, including installation guidance, maintenance tips, and handling any issues that may arise with the product.

Cooperation

Cooperation Process

Get in touch

Send us message if any needs, we will reply you within 24hours