Gym Rubber tile manufacturer

Lanhefloor supplies premium gym rubber tiles engineered for safety, shock absorption, and long-lasting performance. Perfect for gyms, yoga spaces, and functional training zones.

products

Top-Quality Gym Rubber Tiles for Safe and Durable Flooring

Explore our bestselling gym rubber tiles designed for functional areas like weight zones, cardio rooms, and fitness studios — offering unmatched safety, durability, and appearance.

5 stars

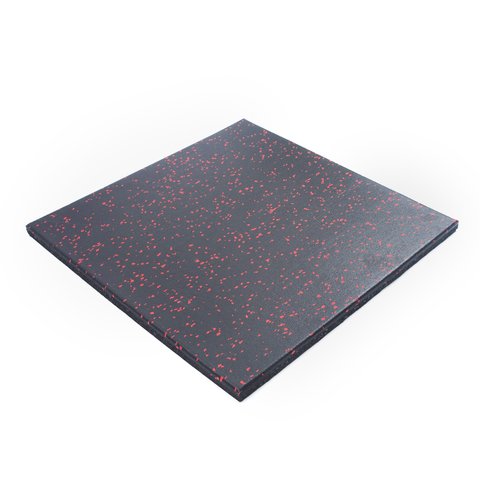

A hybrid tile combining a rubber roll top layer and thick rubber base — ideal for weight areas.

5 stars

Constructed from tiny SBR granules for maximum durability and surface resilience. Perfect for high-impact zones.

5 stars

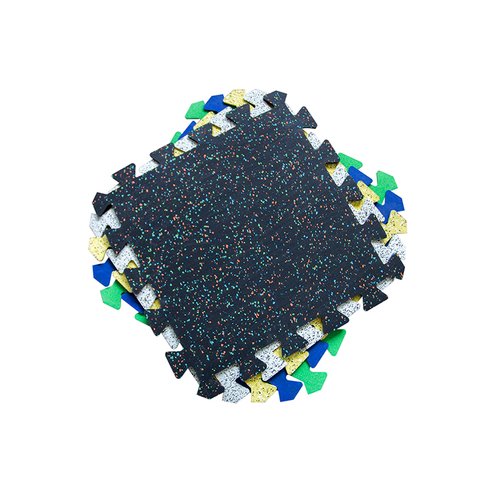

Interlocking rubber tiles for quick installation, tight seams, and easy relocation — no adhesives required.

Features

why choose Lanhe Rubber floor

Explore the key features of Lanhe gym rubber tiles — including safety, comfort, grip, and durability — that make them ideal for commercial and home gym flooring.

Safety

Made from non-toxic rubber materials, our gym flooring ensures a safe environment for fitness areas, schools, and sports zones. Compliant with CE and EN1177 safety standards.

Comfort

Engineered for shock absorption and joint protection, our rubber tiles reduce fatigue during workouts. Ideal for yoga, HIIT, and high-impact training.

Grip

Anti-slip surface with textured finish provides excellent grip, reducing slips in wet zones such as locker rooms, swimming areas, or weightlifting corners.

Cushioning

Provides superior cushioning to absorb shock and reduce fatigue during extended standing or exercise. Ideal for aerobic zones and personal training studios.

Quietness

Sound-insulating rubber structure reduces noise from weights and movement. Perfect for gyms, fitness studios, and multi-purpose wellness spaces.

Durability

Built for high-traffic use, our rubber flooring resists abrasion and compression. Maintains form and function over years of heavy use in commercial gyms.

Our rubber tiles are engineered to suit different training zones — from weightlifting platforms to cardio and yoga areas — offering safety, comfort, and longevity.

applications

Rubber tile Application

Discover how Lanhe gym rubber tiles deliver durable, slip-resistant, and impact-absorbing flooring for gyms, yoga studios, and training facilities.

- Gym Flooring: High-density rubber tiles with excellent shock absorption, perfect for heavy equipment and high-traffic zones.

- Yoga Studios: Soft and non-slip surfaces enhance comfort, flexibility, and stability during stretching and balance training.

- Martial Arts & Combat Zones: Designed with impact resistance and superior cushioning to reduce injury risk during high-impact moves.

process

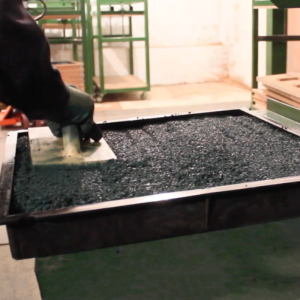

How Rubber Tiles Are Made

From raw SBR/EPDM granules to finished gym rubber tiles, our production process ensures durability, safety, and consistent quality.

Step1 Mixing

High-quality SBR or EPDM rubber granules are thoroughly blended with eco-friendly PU adhesive to ensure uniformity and optimal bonding strength.

Step3 Vulcanization

The molds are subjected to high-temperature vulcanization, activating the bonding agents and forming a stable, elastic rubber structure.

Step2 Molding

The mixed material is poured into molds. For composite rubber tiles, a rubber roll layer is added at the bottom to enhance durability and surface appearance.

Step4 Cooling

After molding, the tiles are demolded and cooled naturally to maintain their shape, hardness, and performance integrity.

pack and ship

Rubber Tile Packaging and Global Shipping

Each rubber tile is securely packed to prevent damage during shipping. Heavy-duty wrapping and protective pallets ensure safe transit.

We ensure all rubber tiles arrive in perfect condition. Each pallet is wrapped in PE film and strapped securely for export. Our team collaborates with trusted logistics partners to arrange fast, damage-free delivery to over 50 countries. Whether by sea, air, or land, your order will be shipped on time and safely.

steps of installation

How to Install Rubber Floor Tiles

1.Preparation

Make sure the subfloor is clean, dry, and level. Remove any dust, debris, or oil to ensure proper adhesion of the rubber tiles.

2.Layout

Plan the tile layout before installation. Start from the center and work outward to minimize cutting and achieve a symmetrical appearance.

3.Adhesive

Spread high-quality rubber tile adhesive evenly on the back of each tile or directly on the subfloor, depending on the product type.

4.Placement

Carefully place each rubber tile onto the adhesive. Press firmly to remove air pockets and ensure a tight fit without gaps.

5.Trimming

Trim the edges with a sharp utility knife to fit walls, columns, or corners. Always measure twice and cut once.

6.Curing

Allow the adhesive to cure for at least 24–48 hours before heavy use. Avoid foot traffic during this time for optimal bond strength.

projects

Global Gym Rubber Tile Projects by Lanhefloor

Discover how Lanhefloor’s gym rubber tiles have been successfully installed in fitness centers, commercial gyms, and training spaces across the globe, offering durability, safety, and performance.

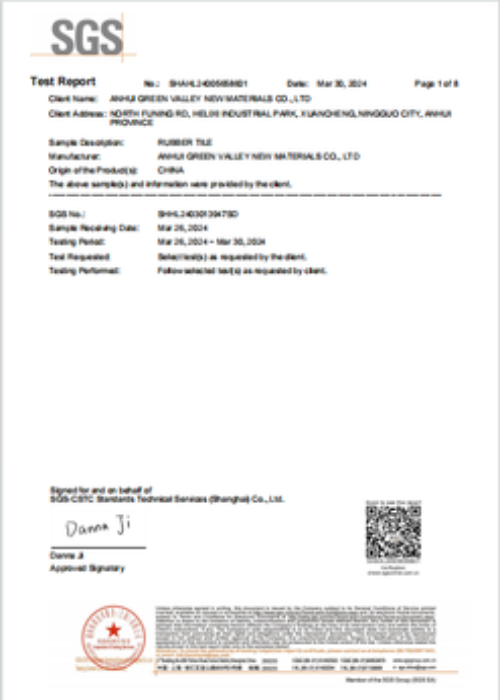

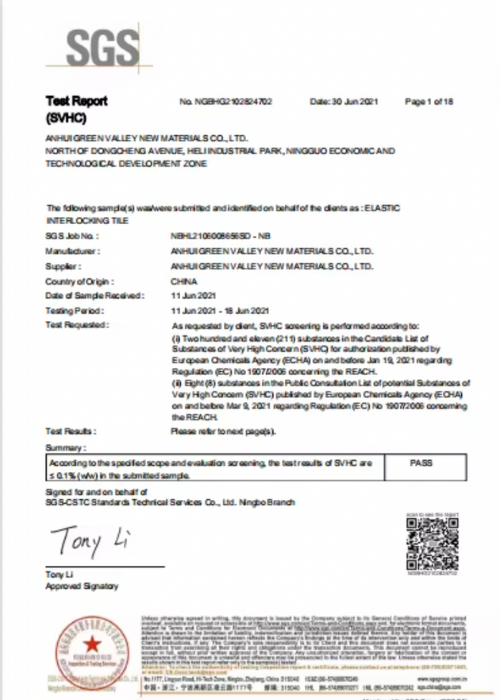

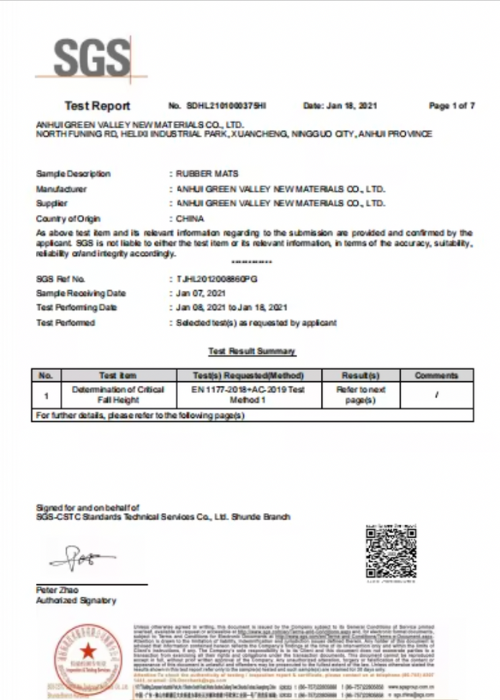

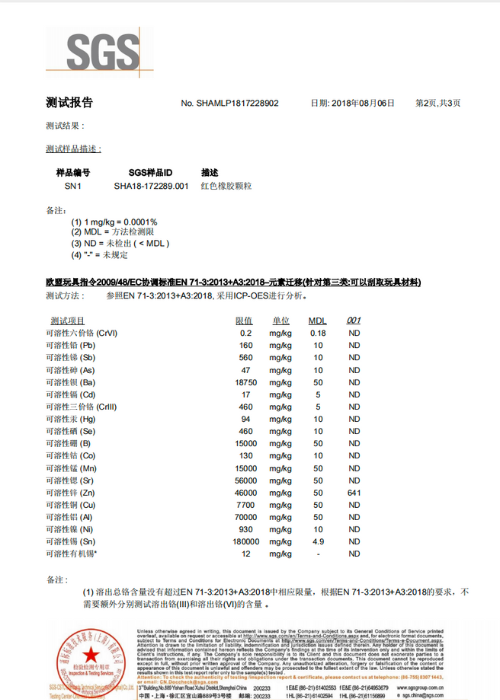

certifications

Certifications That Ensure Safety and Quality

All our rubber flooring products are certified to meet international safety and environmental standards, including EN1177, CE, RoHS, SVHC, and EN71. These certifications ensure our flooring is safe, durable, and eco-friendly, suitable for commercial and sports use worldwide.

Need Help?

Gym Rubber Tile FAQs

Explore answers to common questions about our rubber tiles and rolls, covering product sizes, colors, certifications, installation, and bulk ordering.

What sizes are available?

Our gym rubber tiles are available in standard thicknesses from 15mm to 50mm, and can be customized in dimensions like 500x500mm, 1000x1000mm, or based on your project needs.

What colors can I choose from?

We offer a wide selection of rubber tile colors, including black, grey, and custom speckled blends with red, blue, yellow, and green EPDM flecks. Fully dyed color tiles are also available upon request.

Can I request samples before placing a bulk order?

Yes. Free samples are available so you can evaluate the color, durability, and surface texture before confirming your bulk rubber flooring order.

What payment methods do you accept?

30% TT before production, rest 70% before loading.

How long does it take to process an order?

Standard production time is around 7–15 working days, depending on your order volume and customization. Urgent orders can be prioritized upon request.

How will my order be shipped?

We work with reliable logistics partners to ensure prompt and safe delivery of your order.

What should I do if my order arrives damaged?

Please contact us immediately if any items arrive damaged. We will arrange for replacements or refunds as necessary.

Do you offer discounts for bulk orders?

Yes, we offer competitive pricing and discounts for large orders. Contact us for more details

What if I need to change or cancel my order?

Changes or cancellations can be made within 24 hours of placing the order. Please contact us as soon as possible to make adjustments.

What kind of after-sales support do you provide?

We offer comprehensive after-sales support, including installation guidance, maintenance tips, and handling any issues that may arise with the product.

Cooperation

Cooperation Process

Get in touch

Fill out the form below and our team will respond within 24 hours.