5 Questions You Must Ask Your Rubber Flooring Supplier (Before You Regret It)

Before placing your next flooring order, make sure you’re asking the right questions — or risk delays, safety issues, and costs you didn’t plan for.

If you’re sourcing rubber flooring for gyms, playgrounds, or outdoor spaces, price should never be your first question.

I’ve seen buyers lose entire projects because they chose the wrong supplier — not because the product looked bad, but because the basics were never confirmed. These five questions are what experienced buyers ask before signing anything.

1. Do You Manufacture Your Own Rubber Flooring or Just Resell?

This is the first question — and the most important one.

Many suppliers present themselves as “factories,” but in reality they are traders or agents. That difference directly affects lead time, consistency, pricing, and what happens when something goes wrong.

A true factory like Lanhefloor operates its own 5 production lines, controls raw materials, manages quality in-house, and schedules production based on real capacity — not promises.

| Type of Supplier | What You Get | Real Risk You Face |

|---|---|---|

| Factory like Lanhefloor | Direct pricing, controlled QC | Best choice for stable, large orders |

| Trading company | Easier communication at first | Delays, no production control |

| Individual agent | Fast quotes | No accountability after shipment |

What I always recommend:

Ask for factory videos, raw material sourcing details, and proof of OEM production. If a supplier avoids these questions, that’s already your answer.

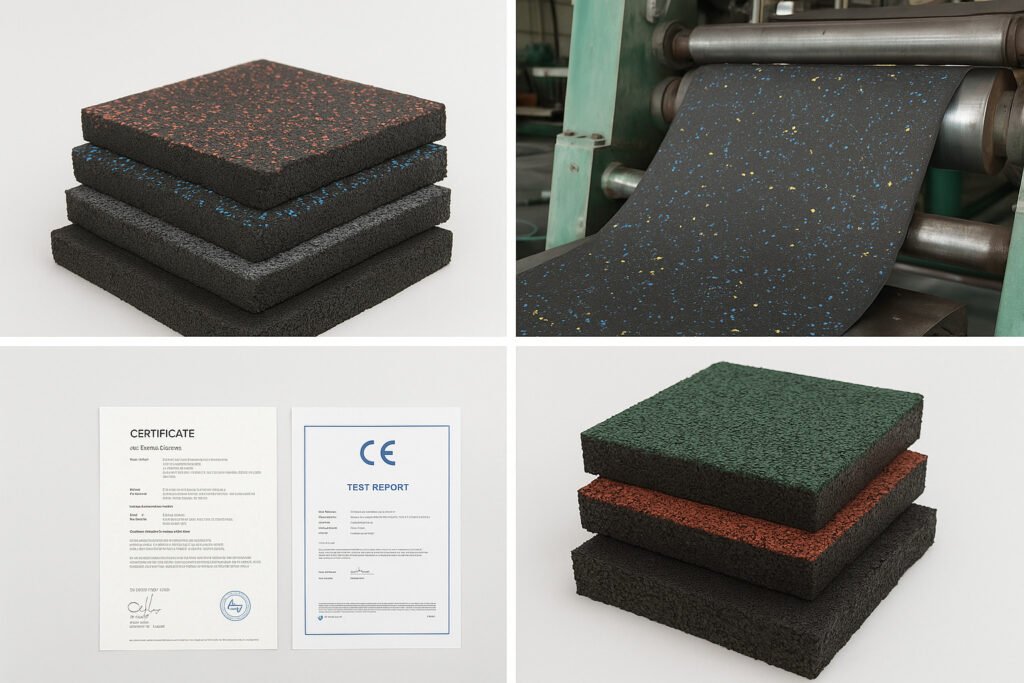

2. What Certifications Do Your Rubber Tiles and Rolls Have?

Certifications are not paperwork — they are risk control.

For gyms, schools, and public spaces, certifications like EN1177 and CE are often mandatory. Without them, problems usually appear after installation, when it’s already too late to fix.

| Product Type | Required Certification | What Happens If It’s Missing |

|---|---|---|

| Gym Rubber Tile | EN1177, CE | Injury risk, insurance disputes |

| EPDM Playground Surface | EN1177 | Failed inspections, legal liability |

| Rubber Roll (Indoor) | CE | VOC complaints, hygiene issues |

I’ve seen buyers trust “certificates” that turned out to be expired or unrelated to the actual product shipped.

👉 For a deeper breakdown, see:

What Certifications Should Gym Flooring Have in Europe?

Always confirm: certificate number, testing standard, and whether it matches the exact product structure you’re buying.

3. Can You Customize Thickness, Color, or Packaging?

Customization is not a luxury — it affects installation, branding, and logistics cost.

Serious suppliers should support customization without turning every request into a problem. At Lanhefloor, this is part of our daily production, not an exception.

We support:

- Thickness from 3mm to 50mm

- Standard and custom EPDM color options

- OEM logo packaging, labeling, and protection layers

| Custom Option | Available at Lanhefloor? | Typical Use Case |

|---|---|---|

| Color customization | ✅ Yes | Branding, zoning, visual consistency |

| Thickness range | ✅ Yes | Weight zones vs. cardio areas |

| Packaging & labels | ✅ Yes | Easier warehouse and resale management |

If a supplier can only offer “standard black” or avoids packaging questions, that usually means limited production control.

4. What Are Your Quality Control Steps Before Shipment?

Anyone can say “high quality.” Very few can show you how they control it.

I’ve handled cases where buyers received flooring with inconsistent density, uneven color, or weak rebound — all problems that were invisible in photos.

At Lanhefloor, our QC process includes:

- Density and weight checks

- Slip resistance testing

- EPDM color consistency control

- Compression and rebound testing

- Photos and videos before shipment

| QC Item | Why It Matters |

|---|---|

| Density & weight | Determines shock absorption |

| Slip resistance | Reduces training injuries |

| Color consistency | Prevents patchy floors after install |

| Packaging inspection | Avoids damage during sea transport |

📘 Related reading:

Rubber Flooring Durability Guide

If QC is not documented, quality is just a promise.

5. What Is Your Lead Time and How Do You Handle Delays?

Lead time problems don’t show up on quotes — they show up when your project is already late.

Factories without raw material stock or production planning often miss deadlines, especially during peak seasons. That delay usually costs more than the flooring itself.

Lanhefloor standard lead times:

| Order Size | Typical Lead Time |

|---|---|

| 100m² Rubber Roll | 7 working days |

| 500m² Rubber Tile | 12–15 working days |

| 5 Tons EPDM Granules | 10–14 days |

We maintain material stock, operate 5 production lines, and provide real-time production updates, including container tracking once shipped.

📦 Related post:

Gym Flooring Order Process

Always ask how delays are communicated — silence is the real risk.

✅ Conclusion: These 5 Questions Protect Your Project

Choosing a cheaper supplier often becomes the most expensive decision later.

Before placing any order, make sure you can clearly answer:

- Who actually makes the product?

- Are certifications real and relevant?

- Can the product be customized?

- How is quality controlled?

- What happens if timelines change?

🔗 Further Reading

- EPDM vs. SBR Rubber Flooring

- How to Choose the Best Rubber Flooring for Your Gym

- Rubber Tiles vs. Rolls for Gym Flooring

- Rubber Flooring for Yoga Rooms and Office Spaces

- Is Rubber Flooring Safe for Outdoor Playgrounds?

💬 Need advice before you request pricing?

If you’re not sure which product, thickness, or structure fits your project, start with a conversation — not a quote.

👉 Get in touch now

Or email us at info@lanhefloor.com with your application details, and we’ll suggest the right solution first.