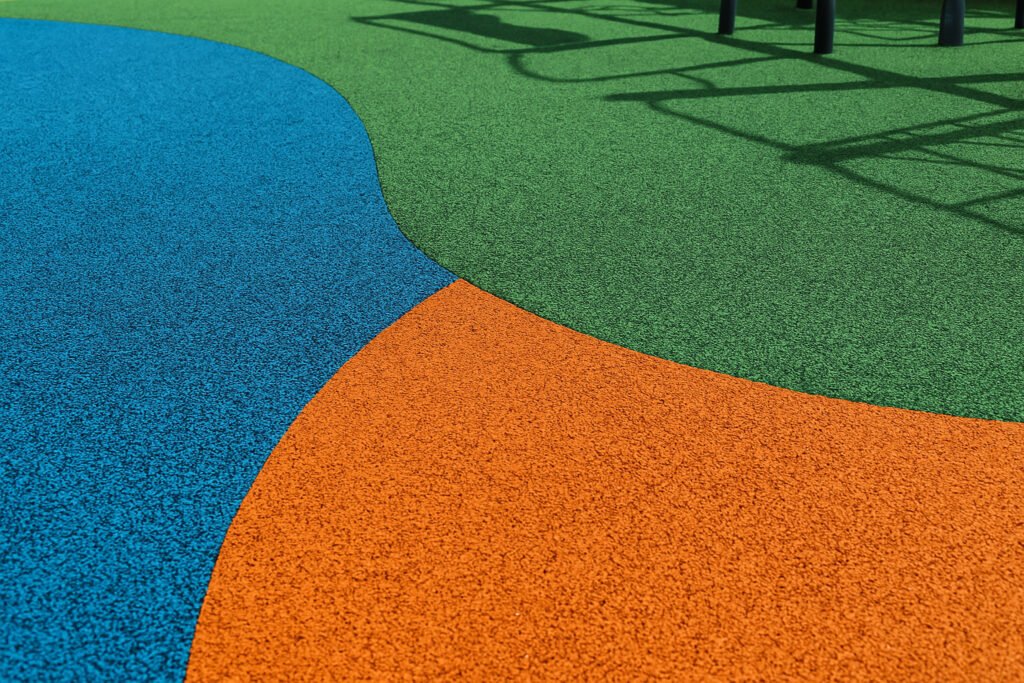

How to Choose Reliable EPDM Granules Suppliers in China?

Many contractors struggle with color inconsistency, poor elasticity, and delayed delivery when buying EPDM granules from unknown suppliers.

Reliable EPDM granule suppliers in China must meet strict standards in color stability, binder compatibility, batch consistency, certification, and export packaging. Choosing the right supplier prevents costly on-site failures.

Many buyers share stories about project delays or surface failures caused by low-quality granules. I wrote this guide to help you avoid these risks when sourcing EPDM from China.

What Makes EPDM Granules “Reliable”?

Some buyers focus only on color, but true EPDM quality depends on multiple technical factors. Understanding these elements helps you choose a trustworthy supplier.

High-quality EPDM granules should offer strong UV resistance, consistent granule size, stable color, and safe materials suitable for outdoor installations.

Key Elements of High-Quality EPDM Granules

Proper Binder Compatibility

The granules must bond smoothly with PU binder. Poor bonding causes cracking, shedding, and early surface failure.

UV and Color Stability

Good EPDM granules maintain bright colors under sunlight. Low-quality materials fade quickly, especially yellow, blue, and green.

Uniform Granule Size

Common sizes are 1–3mm and 2–4mm. A consistent size ensures a smooth installation and even surface texture.

Non-Toxic, Fresh EPDM

Reliable suppliers use fresh EPDM—not recycled rubber. Fresh material offers better elasticity, safety, and weather performance.

Comparison Table: High vs Low Quality EPDM

| Feature | High-Quality EPDM | Low-Quality EPDM |

|---|---|---|

| UV Stability | Strong | Poor |

| Color Consistency | Stable | Large variation |

| Elasticity | Durable | Turns powdery |

| Safety | Non-toxic | Mixed recycled |

| Binder Compatibility | Smooth | Weak bonding |

Common Problems Buyers Face When Sourcing EPDM in China

Many overseas buyers experience similar challenges when working with unreliable factories.

Most problems happen because suppliers reduce costs by lowering EPDM purity or mixing SBR granules.

Common Issues

Severe Color Difference

Different batches have visible color variations, causing uneven playground or track surfaces.

Incorrect Binder Ratio

Low-quality EPDM forces installers to adjust PU binder content, increasing installation difficulty.

Fake Certifications

Some suppliers use outdated or invalid EN1177 or CE certificates.

Production Delays

Small workshops often fail to control production schedules, causing project delays.

Sample vs Bulk Difference

A common complaint: “Sample is good, bulk order is totally different.”

Weak Export Packaging

Cheap bags break during shipping, allowing moisture and contamination to damage the granules.

Why These Problems Matter

Poor EPDM can lead to:

- Early cracking

- Rapid fading

- Surface powdering

- Complaints from end users

- Expensive repairs

How to Evaluate a Reliable EPDM Supplier in China

Here is a practical checklist based on real sourcing experience.

1. Check Production Capacity

Reliable manufacturers should have:

- Continuous mixing systems

- Stable temperature control

- Professional coloring lines

- UV aging test equipment

2. Verify EN1177 & CE Certificates

Request:

- Original PDF

- Traceable certification number

- Testing organization name

If they cannot provide this, consider it a warning sign.

3. Review Their Previous Projects

Reliable suppliers will show:

- Playground installations

- Running tracks

- Sports court surfaces

View our project cases:

https://lanhefloor.com/projects/

4. Ask for UV and Aging Test Reports

Bright colors especially require strong UV resistance.

5. Check Granule Size Distribution

The granules should not contain excessive powder or oversized particles.

6. Evaluate Packaging Quality

A reliable supplier uses:

- 20–25kg strong bags

- Inner moisture-proof lining

- Shrink-wrapped pallets

7. Test Communication Quality

Slow or unclear communication often reflects weak management.

8. Request Same-Batch Samples

This helps you verify batch consistency before mass production.

Supplier Evaluation Checklist

| Item | Good Supplier | Bad Supplier |

|---|---|---|

| Certificates | Verifiable | Unclear |

| Packaging | Strong bags | Weak bags |

| Color Control | Very stable | Poor |

| Response Time | Fast | Slow |

| Sample vs Bulk | Consistent | Different |

Why Many Buyers Prefer Chinese EPDM Manufacturers

China is one of the largest producers of EPDM granules in the world.

Advantages of Chinese Suppliers

Stable Raw Materials

Major factories have consistent access to raw EPDM compounds.

Flexible Color Customization

Chinese suppliers can create custom colors for playgrounds, logos, and sports courts.

More Competitive Pricing

Economies of scale lower overall cost without sacrificing quality.

Strong Export Experience

Most factories understand global packaging and shipping requirements.

Explore EPDM granules from our factory:

https://www.lanhefloor.com/epdm-granules/

https://lanhefloor.com/outdoor-rubber-floor/

Red Flags to Avoid When Choosing EPDM Suppliers

These warning signs often lead to quality or delivery problems.

Key Red Flags

Extremely Low Prices

Suspiciously cheap offers often include:

- Mixed SBR

- Weak pigments

- Low elasticity

No Factory Photos or Videos

A reliable manufacturer is transparent.

Fake or Unverifiable Certificates

If documents look unclear or outdated, be careful.

Poor Packaging

Thin or unsealed bags increase transportation damage.

Slow or Unclear Communication

A major sign of weak organization.

Red Flag Table

| Red Flag | Possible Risk |

|---|---|

| Very low price | Mixed recycled materials |

| No certificates | No testing or compliance |

| No factory video | Trading company |

| Weak packaging | Moisture damage |

| Slow reply | Poor service |

Why Lanhefloor EPDM Granules Are Trusted by Global Buyers

We export EPDM granules to Australia, Canada, Japan, the Middle East, and Europe for playgrounds, sports surfaces, and public areas.

What We Offer

Stable Binder Performance

Compatible with standard 22% PU binder.

Excellent Color Stability

Colors stay bright even under strong UV exposure.

100% Fresh EPDM

We do not mix recycled SBR in EPDM production.

Verified EN1177 & CE Certifications

Documents are fully traceable.

Professional Export Packaging

25kg bags, palletized, and shrink-wrapped.

Fast Lead Time

Our 5 production lines support large-volume orders.

More information:

https://www.lanhefloor.com/epdm-granules/

Conclusion

Reliable EPDM suppliers in China must provide stable color, verified certifications, proper packaging, and consistent quality. The right partner helps your project stay safe, long-lasting, and problem-free.

If you need samples, technical data, or advice for your EPDM surface project, I’m here to help.